Power Drill Buying Guide

This post contains affiliate links. As an Amazon Associate, We may earn commissions from qualifying purchases made from our chosen links.

A power drill is an essential tool you can own for all your building and construction tasks. With a good power drill at your disposal, you will be able to complete your DIY projects quickly and easily. Our comprehensive guide will explain everything you need to know about drills and will help you decide on the best one for you.

Types of Power Drills

Drill Driver

Drill-drivers combines the features of both a drill and screwdriver, giving you a 2-in-1 tool to help you drill holes and turn screws. These type of drills are handy for a diverse range of home improvement tasks. You can use them to hang pictures, construct DIY furniture, or even fix up broken wall and ceiling fixtures around the house.

Drill drivers feature a keyless chuck, to let the operator quickly to swap between a selection of drill bits. These type of drills are some of the most common power drills you can find, because of their high level of versatility when it comes to home improvement tools.

One of the most significant drawbacks of drill drivers is that it doesn’t have a hammer-action function. This means that even with a high power drill driver, you won’t be able to work on extremely durable materials like concrete or steel.

Right-Angle Drill

Right angle drills (or sometimes called close quarter drills) lets you work on tight and small spaces that standard-sized, straight-angled drills can’t reach.

Because of their size, weight, and versatility, artisans, and professionals like carpenters, plumbers and electricians find right angled drills an invaluable power tool for their line of work.

Right angle drills are excellent for tasks such as pipe installations, threading electrical wiring, or any project that requires holding a power drill at awkward angles for long periods.

Hammer Drill

Hammer drills are a similar design to standard drill drivers, but they include one crucial feature – it has hammer action.

Hammer action is a mechanism that drives the drill bit in a forward pulsating motion as it rotates, which increases the drilling power.

Hammer drills usually come in higher speed operations than other standard drills too. With the additional drilling power and speed, you can work on projects that require tough materials, such as concrete, brick or other types of masonry surfaces.

Rotary Hammer

A rotary hammer (or demolition hammer) drill is similar to a hammer drill. Both drills feature a forward pounding motion during operation, but a rotary hammer creates its pounding action using an air pressure-driven piston.

With the piston, rotary hammers provide a lot more impact than standard hammer drills. Most rotary hammers come with three operation settings, including a hammer-only mode, which transforms the rotary drill into a mini jackhammer.

Because of its added power and features, rotary hammers also costs more than hammer drills. You can find rotary hammers in the toolbox of most professionals in the construction or demolition business. For most home DIY projects, a hammer drill will suffice.

Screw Gun

Screw guns operate similarly to a drill, but they are designed for one primary purpose – to drive screws. If you need to work on hundreds of screw for a project, a screw gun can save you tons of time and energy compared to a manual screwdriver.

Screw guns usually operate at a higher RPM (revolutions per minute) than drills.

Both screw guns and drills are not exclusive to their primary purpose – meaning you can use a screw gun or drill for BOTH driving screws and boring holes, but you should choose the right tool that fits your project and task.

Types of Power Sources

Like most power tools in the market today, power drills only come in two kinds of power source – corded or cordless. In general terms, a corded drill is going to be more powerful than a cordless drill.

A power cord can supply virtually limitless electrical energy to the corded drill, allowing the drill to operate at a steady speed and power of up to 110v.

On the other hand, a cordless drill can only run on up to 20v at the most, which is over five times less voltage than a corded drill. However, the voltage level is not an accurate indicator of a drill’s power. The main feature of a drill is its speed and RPM.

Thankfully, cordless drills have gained significant improvements, with the ability to match both speed and RPM as their corded counterparts.

At the end of the day, choosing a corded or cordless drill is mostly dependent on your requirements. Do you need a convenient drill to work at places where a power outlet is far away, or do you need a drill that can function for hours at a time without losing battery power?

Types of Drill Motors

You will usually find two types of motors inside a drill – Brushed (for DC) power, or brushless (for AC power).

Brushed Motors

Brushed motors operate in direct current (DC). The advantages of brushed motors are that its design is basic; its speed and torque can be easily regulated, and the torque-to-motor speed has a linear relationship.

Simply put, in brushed motors, the bigger the motor, the more torque you will get. But with simplicity comes with a few drawbacks as well. When operated at lower torque speeds, controlling the motor becomes unreliable.

Also, brushed motors require regular cleaning because it produces dust operation. If there is too much excess heat or physical abuse, the motor can loosen and weaken over time.

Brushless Motors

Brushless motor technology has increasingly popular in the power drill market in the past few years. While brushless motors aren’t a new innovation in power tools, several prominent power tools brands such as Makita and Dewalt have released a lineup of brushless motor tools, bringing brushless power tools to popularity.

Inside a brushless motor drill, the motor adjusts its torque according to the task. Unlike a brushed motor drill that operates only at maximum capacity, when the brushless motor drill encounters resistance during operation, it draws more power from its source. This means huge savings on your cordless drill battery life, and you can work with your drill for extended periods.

Brushless motors also don’t get the friction or drop in voltage that standard motor brushed motors get. This means you can expect an increase in the lifespan of the motor and long term performance.

However, the cost is a factor for a brushless motor. Because brushless motors are more difficult to design and build, they are usually more expensive.

On average, a brushless power tool can cost 30% more than other standard power tools. However, because of their performance and reliability, most tradespeople and professionals prefer to work with a brushless power drill daily.

Types of Battery

When it comes to power tools, your source of power is just as important. During your cordless drill buying process, you’ll need to make an additional decision of choosing the battery type. Currently, there are two types of drill batteries in the market: Nickel-cadmium (NiCd) or lithium ion.

Nickel-Cadmium

NiCD batteries are both low cost and durable, making them a natural choice for a battery source. However, NiCD batteries have a reputation for having the “lazy battery effect”. That means if you don’t discharge the battery until it is 0% when you use your drill, it will gradually lose its charge capacity. Despite this shortcoming, you should still give this kind of battery a chance.

As one of the oldest type of batteries, NiCD batteries have a long lifecycle, high resistance to extreme hot and cold temperatures. Also, compared to other batteries, NiCD has a short recharge time. Even at lowered capacity, they can produce a consistent power output.

As an owner of NiCD batteries, you will need to perform periodic maintenance to ensure your batteries can last for a long time. One thing to note about NiCD batteries is that they are toxic to the environment, and will require proper disposal before they can be recycled.

NiMH (Nickel-Metal Hydride)

NiMH batteries are improved version of NiCD batteries. With two to three times more capacity and only minimal lazy battery effect, NiMH batteries are worth the investment if you are looking for power drill batteries.

While NiMH batteries don’t have the same temperature resistance of NiCD, they carry a higher energy density.

NiMH also has a slightly shorter overall lifespan, but they are also less harmful to the environment. To maximize its overall lifespan, NiMH batteries must be kept and maintained correctly.

Lithium Ion (Li-Ion)

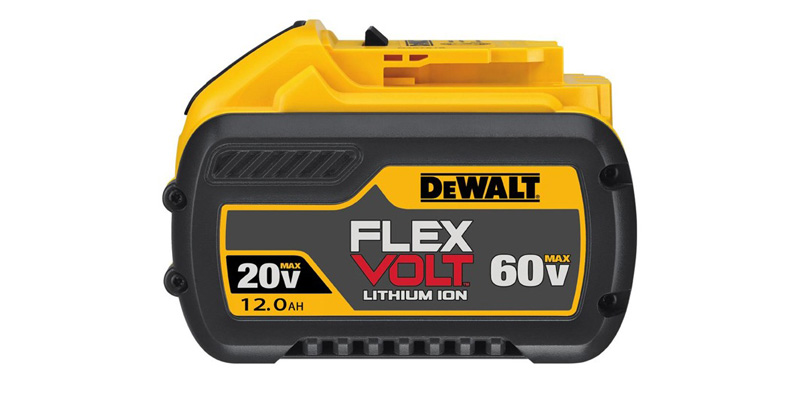

This type of battery is probably the one that you are most familiar with. Commonly found in most modern electronics such as cellphones and laptops, Li-Ion batteries are the most expensive option out of the three. That’s because Li-Ion carries the latest and most significant battery improvements. Despite having the shortest lifespan, they are lightweight and pack a high charge capacity. You won’t find any memory effect either, but they are highly susceptible to damage from high heat.

With Li-Ion batteries, you don’t need to carry out any regular maintenance. But unlike nickel batteries, Li-Ion batteries lose their power output as they deteriorate, affecting the performance of your drill.

Choosing The Right Drill

Here are some key considerations for you to think about when you’re picking up a power drill. Think about what you’ll be using your new drill for.

- What kinds of surfaces will you need to drill into?

- Will you be working on soft materials such as wood and soft board?

- Are you going to be drilling on hard concrete or stone surfaces?

- Alternatively, perhaps a mix of both hard and soft materials?

- How long at a time will you be operating your drill?

The three most popular power drill options are:

Drill Drivers

If you are working on mostly indoor or materials that are mostly soft-medium toughness, a drill driver will be your best option.

Hammer Drills

With the additional forward impact movement, hammer drills are perfect for working on tough materials. However, hammer drills are not recommended for wood projects. Also, they are much louder than drill drivers so you will require ear protection during operation.

Rotary Hammers

Rotary hammers are the most powerful option out of the three drill types. These will chew through the toughest materials for your project, but they are usually overpowered for all but the most demanding home projects. If you’re unsure that you need to buy a rotary hammer, you can always start by renting one from your local hardware store first.

Drill Features to Consider

- Battery

Battery capacity in power drills are measured in amp-hours (Ah). The amount of operational hours you get with your power drill depends on the number of amp-hours and the voltage your drill uses. Battery capacity isn’t only about drill runtime. Higher capacity batteries can deliver more power to run the drill faster.

It can become confusing when you look at all the different types of batteries available. With newer models and technology, it is nearly impossible to keep track of them all. Make sure you speak to your in-store sales representative about battery capacity before you buy to get the latest information about battery capacity.

- Clutch

Just like a car, most drill-drivers come with a clutch that lets you control the level of torque during. The clutch automatically disengages the drill bit from the motor when the torque exceeds its preset value. When your drill has a clutch, it should also come with multiple speed settings. A low setting is suitable for driving drywall screws, while a high setting is useful for driving screws into hard surfaces.

- Chuck Size

The chuck size of your drill can be very crucial, depending on what type of usage you are planning for your drill. In general, the larger the chuck, the larger drill bits it can hold. That means you can drill bigger holds, driver bigger screws. When in doubt, choose a large chuck so that you can use more bit sizes.

- Grip Comfort

The comfort of a power drill is mostly determined by two factors: the weight and grip of the drill (handle comfort). Because the grip comfort is secondary to the functionality of the drill, most people overlook the importance of a comfortable drill grip.

Having a well-balanced drill will keep your hands and wrist away from fatigue after prolonged use. On the other hand, a bulky power drill wears out your hands quickly.

A vulcanized rubber grip handle can improve your grip strength when handling your drill, but some rubber grips can wear out and become sticky when they are left unused for a long time. Some other comfort features include a lock button that lets the drill continue to operate without having you to keep your finger on the trigger.

- Reversibility

Having a drill that can spin in reverse can be very useful. For example, you accidentally end up driving a screw into the wrong spot. With a reversible drill, you can quickly remove the screw and fix the mistake without having to reach for your screwdriver. A reversible drill can also be used to clean up a hole and remove any debris stuck inside.

Conclusion

Choosing the right power drill can be tough when you don’t know what to look out for.

The key is to choose the right drill for the right task. Think about what, where and how you are going to use your new drill before you step into your hardware store.